A Different Kind of Dairy - Strasser Natur Bauernhof

- Chris and Leah

- Sep 3, 2019

- 8 min read

Updated: Nov 6, 2019

Like the other farms we experienced in Austria, Strasser Natur Bauernhof (Natural Farm) began as a dairy operation. Our host, Robert, inherited the 100 acre farm from his father. Growing up on the farm, he noticed many of the challenges of a small dairy and decided to change things. Currently, this farm is a milk processing center, turning local Organic milk into raw cheeses, butter, cream, and buttermilk with the help of Robert's inventive ideas and his farm partner Tina's added education in merchandising and sales.

Shifting the operation has allowed Robert to focus on marketing high-value products instead of caring for dairy cows. He does raise a few pigs for home use. The largest fields on the property are rented to neighbors for making hay for their dairy herds. The milk comes from two other farms, both within 5 miles. Milk is picked up in a bulk tank trailer pulled by the farm delivery van. He usually picks up milk 3 days per week.

We visited both the farms that provide Robert with milk. Both are Organic family farms, one with 40 Fleckvieh dairy cows, the other with about 70 Holsteins. Robert pays the farms the going rate for milk (i.e. whatever the local coop would pay). However, he picks up the milk himself, making the job easier for the dairies and saving them a little time and fuel.

Of course, buying-in milk is an expense, but for Robert the benefits outweigh the costs. He doesn’t have to milk every day or make hay to feed his herd. This frees up time to concentrate on finding buyers and getting more sleep. In addition, he can forecast his income based on the prices he sets for his products, rather than the ever-changing price the milk co-op will pay. With the help of robust sales outlets, Robert has been able to smartly invest more in the dairy processing business by purchasing various new or used equipment in good condition to help grow a sustainable customer base.

Unique among all the other farms we have worked on, this business is structured as an ‘Association’. The translation is not exact, but it’s something like a member owned co-op. Robert did lots of research into taxation and sales laws for raw-milk products and found that this business model gives him the most flexibility, the least liability, and lower individual taxes.

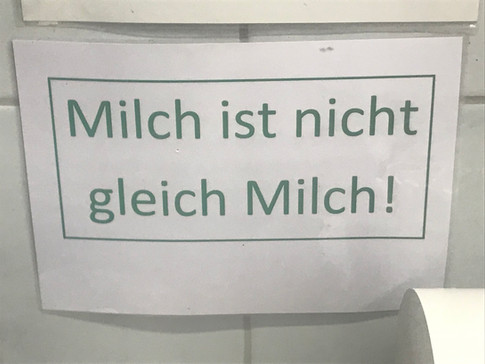

Customers join the ‘co-op’ by paying a membership fee and committing to buy a certain amount of product on a monthly or annual basis. In turn, the farm can sell raw-milk products to members without additional government oversight or taxes. Austria’s rich dairy history means there is a pretty savvy customer base who are aware of what raw products are, their risks, as well as their benefits. "Milch ist nicht gleich milch." Milk isn't just milk.

The Products

Butter - Strasser Natur Bauernhof is known for their raw-milk butter. It is a non-pasteurized, cultured butter product, which means the milk is soured for 24 hours in an open vat before it is churned into butter. The milk is then drained into the butter churn machine, which makes 100lbs. of butter per batch. The churn is electric and takes less than 5 minutes to finish the job, as long as the milk is fresh.

Once it’s complete, the buttermilk is drained off and sold as a separate product. The butter is then scooped into plastic bins and put in the cooler (38F) to chill. Once it is chilled, it is brought to another machine that gives it a standardized shape and cuts it into blocks that weigh 250grams (about 9 oz.). The farm logo is pressed into each by hand with a heavy stamp. The butter blocks are then packaged and returned to the cooler until they are shipped, delivered, or taken to market.

This product has especially found wide appeal among chefs in expensive hotels in central Vienna. Bread and butter traditionally appear at nearly every meal in Austria, making this a lucrative market. Raw milk products in general appeal to customers that want to avoid pasteurization and prefer a ‘living’ product.

Cheeses – The farm produces a variety of cheeses, but specialize in a few local specialties like cooked cheese, gray cheese, topfen (Quark), caraway seed, and beer cheese. These cheeses are all made with lowfat to no fat milk, unlike many other European style cheeses, which allows the farm to market other full fat products like the butter and cream too. Cooked and gray cheese are traditional Austrian cheeses that Robert’s grandfather made in the cellar back in the day. The family and old farm house held a lot of history, including being a safe place for people to work and help with daily farm chores like milking and hay making when times were tough during World War I. Robert’s family property and house was one of the largest in the area at that time which allowed for them to offer opportunities to people outside of their family.

Cooked and gray cheeses are unique in that they are acid-curdled cheeses, which do not use rennet. These cheeses are common in the Tyrolean Alps. These cheeses are made using the same technique as the butter, where the milk is ‘cultured’ or rests for 24 hours before any processing. Cooked cheese is actually curd that is reheated and mixed with some butter. Gray cheese is very lean because it is made from milk left over from butter production which has less than 2% fat. After heating, the curd is drained and then broken into pieces before setting into molds. Once the cheeses age for two or three weeks, they develop grayish-green fungal molds. The texture and smell are very different from most cheeses, with a strong funkiness that comes from the culturing. After bacteria are added to separate the curds and whey, there is usually another step involved to make a cheese with a consistent texture. Instead, these cheeses show the individual pieces of curd visible resulting in a unique texture and appearance.

Other specialty cheeses we helped make were washed rind beer cheese and a washed rind caraway seed cheese. The washed rind technique was new and interesting to us, however, it was slightly smelly and messy too. Essentially, washed rind cheeses are brushed with a brine of bacterias, salt, and water giving the cheese an orange-reddish color. Doing this fosters an environment hospitable to a variety of bacteria allowing the cheese to take on a unique texture and pungent smell. Depending on the level of moisture, washed rind cheeses will either become creamy and oozy (high moisture content) or firmer and drier (low moisture content) with age. Robert's beer cheese was brushed twice each week for 3 weeks to achieve the desired quality of a somewhat firm, dry-ish rind before being packaged. This process is quite labor intensive but the end product can be sold for more and the smell and texture appeals to certain crowds, especially his market in Salzburg.

Cream – Along with the buttermilk produced as a byproduct of butter making, Robert also captured full fat cream from the bulk tank by using a mechanical separator. As the fresh milk was heated in the bulk tank coming off the trailer, the cream and milk were separated with a machine consisting of dozens of stacked plates that efficiently funneled the cream and part- skimmed milk into two different vessels. The cream would then chill in the cooler for a day to be sold as heavy cream or longer to be sold as sour cream.

The Markets

We got an inside look at some creative marketing approaches that we have not seen elsewhere. The variety of markets they have are a good way to reduce risk in any single market and to reach different groups of potential customers. They attend a weekly Saturday farmer’s market in Linz, the second largest metro area in Austria. In addition, there are weekly product deliveries to grocery stores, hotels and restaurants. The members of the association either pick-up products directly at the farm or have them mailed out on a weekly or monthly basis.

The mail order part of the business was an interesting surprise. They use an overnight delivery service to reach a wider client base across Austria and Bavaria in Germany. The cheese, butter, and sometimes raw-milk are packed into insulated foam cooler boxes on Mondays. The boxes are picked up by a courier at the farm Monday afternoon and are delivered on Tuesday morning. Customers receive the order and return the box, which is then delivered (empty) back to the farm on Wednesday. Another order is packed inside and shipped on Thursdays, and the boxes make it back to the farm on Saturday. They are able to use them twice each week. Robert has one paid employee who works 32 hours per week, Monday – Thursday packing and shipping the orders.

The newest market outlet was in process while we were at the farm. Robert was nearly finished with construction of an on-farm store. It is a room with shelving and coolers for the cheese, milk, and butter, but will also carry produce from nearby growers as well as other local processed products. Members of the coop will contact Robert and receive the digital door lock code that will give them access to the store. It will use an honor system cash box for payment, which will be collected at the end of each day. The combination of the lock code and a security camera inside are intended to deter theft in the store, which is at the front of the property closer to a main road that connects various nearby towns. Robert thinks the location and direct farm sales will give him an edge over competition.

The Adventure

This farm was located just north of the ‘Salzkammergut’ a beautiful area of alpine trails and lakes. We were lucky to get a chance to check some of it out with the car Tina loaned us in the afternoons when the workday was done. It was especially fortunate since there was a bit of a heat wave in Austria then, making the work inside the production facility very hot and sweaty.

Our favorite memory was driving down to Attersee to a popular ‘beach’ on this turquoise alpine lake. There aren’t sandy beaches in the area, but most of the parks on the lakes have a nice grassy lawn leading down to the lake access. Like any good Austrian spot where people congregate, you can buy sausages and beer at the snack bar and enjoy the lakefront and mountain views.

We also had a couple days before heading to the farm to check out Salzburg, which is a lovely city with far too many Mozart chocolates for sale. Although we got gray weather while visiting, the city, its parks, and the river were all very beautiful- like most things in Austria. We thoroughly enjoyed a Stiegl too, one of our favorite beers, right in the city where it's made! Apparently the locals think Stiegl is subpar compared to other options and brands, but we were more than okay with drinking it. We also went to a neat beer garden which was formerly a monastery turned into a brewery called Augustiner Bräu. Here the monks only brew one style of beer but customers have dozens of food options to eat in the tree covered garden that reminded us of the UW-Wisconsin Union.

We are a little behind on this blog of ours, so more to come soon from England (and maybe the Balkans if we have time)! Thanks for following.

What an incredible adventure the two of you are having! I love experiencing some of it vicariously!